Sustainability

Reduce, Reuse, Recycle

Erik Thorstensson, our Chief Innovation Officer and inventor behind Strawbees, is a mechanical engineer specialized in environmental product design: “We are a company full of young aspirational engineers, environmentalists, developers, creatives and educators. To aim for a closed-loop system and to reduce, reuse and recycle is simply part of our DNA.”

Erik Thorstensson got awarded the ‘Entrepreneur of the Year Swedish Recycling Award 2011’, inspiring the next generation to reduce and prevent waste.

Erik Thorstonsson’s got awarded the ‘Entrepreneur of the Year Swedish Recycling Award 2011’, inspiring the next generation to reduce and prevent waste.

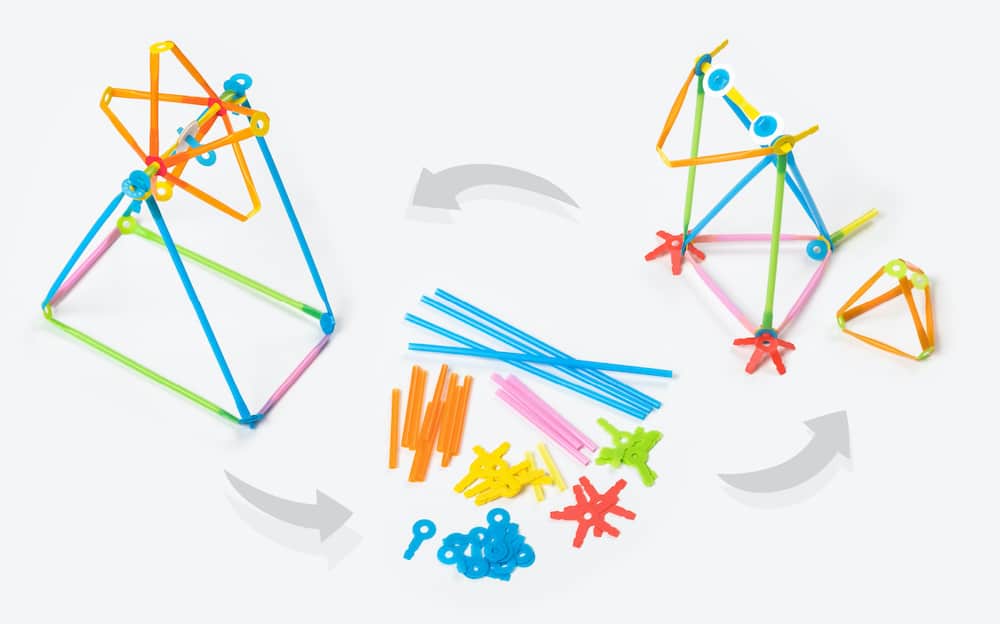

Our multi-use straws are designed to be used over and over again. The benefit of using high-quality plastic in the shape of a straw means we can use much less plastic and our structures become very lightweight. This way we optimize material usage by student per year and we can even make things that fly!

This aligns with the first principle of Environmental Responsibility:

Reduce!

This aligns with the second principle of Environmental Responsibility:

Reuse!

This aligns with the third principle of Environmental Responsibility:

Recycle!

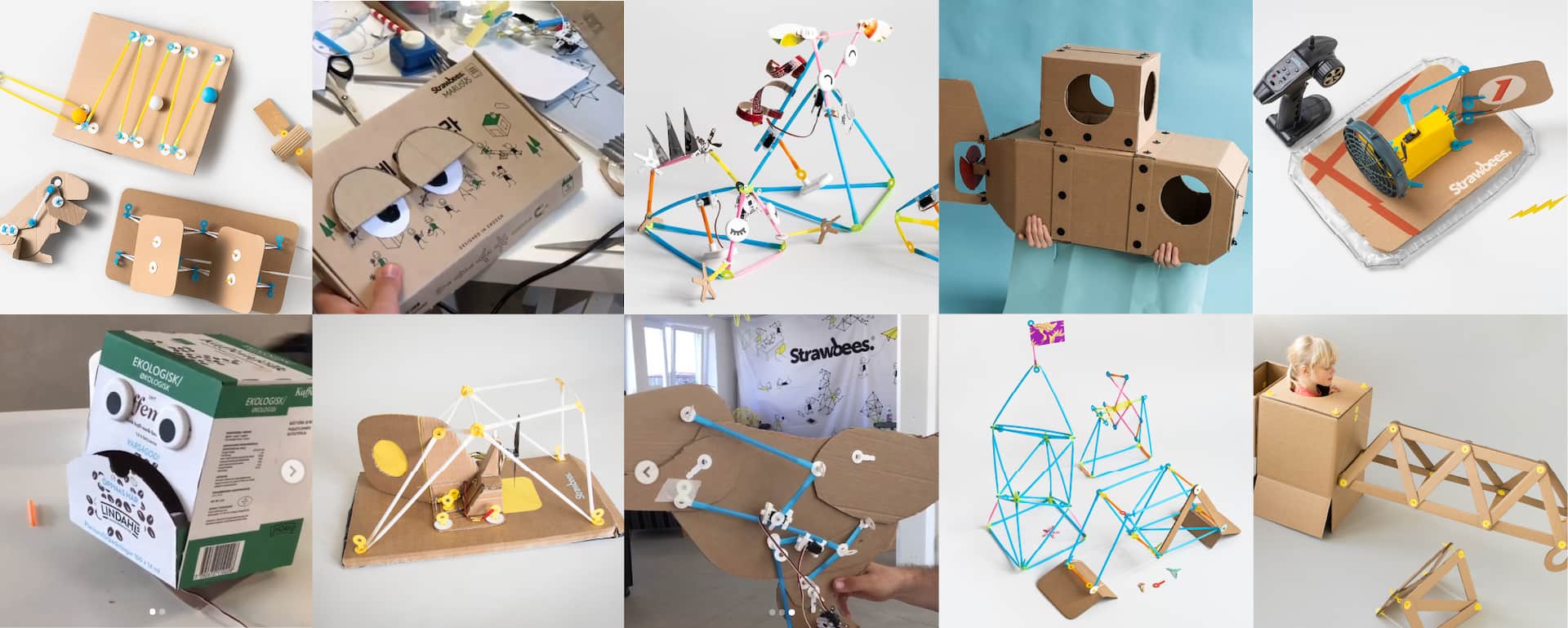

Sustainable tinkering

Help us spread the word! Watch our video below on how to transform waste materials into usable building blocks; understanding manufacturing and waste management; learning about material properties and prototype solutions for environmental issues; and how to integrate sustainable practices.

Check out our Cardboard School Kit and Hovercraft too. Those encourage kids to get creative with cardboard, upcycled and recycled materials. And our Sustainability Station is where you can physically create your own Strawbees using household waste. Email us at recycle@stage.strawbees.com to find out more.

Multi-use cycle

If you like the look of our cool Multiuse Cycle posters, download it here for your classroom.

Chalmers Industriteknik (Industrial Technology)

To find out about the additional research we’re currently conducting, all backed by Chalmers Industriteknik, an independent expert in material science, please email info@stage.strawbees.com.

Chalmers, an outward-looking university of technology is:

Proud to partner with Strawbees. The focus of the research and development is exploring the company’s material science avenues including investigating the novel plastic fuser ‘closed-loop’ recycle innovation by Erik Thorstensson further and backing Strawbees material choices scientifically.

Kent Rundgren, Project Leader

Chalmers Industriteknik

NESTE

Together with Neste we are working to replace the plastics used in our products with materials from renewable sources and to contribute towards a circular bioeconomy.

Neste on Accelerating circularity

neste.com